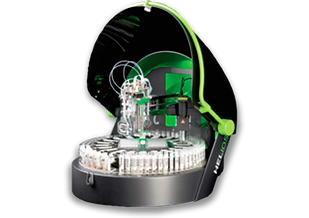

HELIOS is a revolutionary system which automatically carries out the complete pipetting and the selections of IFA (immune fluorescence) tests.

It is the first and only system which takes over this process completely from beginning till the end. Compared with the manual procedure, HELIOS counts an absolute proof control to its signs beside an uncomplicated use and a maximum saving of time.

HELIOS® AUTOMATED IFA SYSTEM

Fully automated IFA Processing + Reading

HELIOS® AUTOMATED IFA SYSTEM

HELIOS® AUTOMATED IFA SYSTEM

Three needles

speeds up the process, ensures timing per well, prevents slidings drying out.

IFA Processor

is based on the HELMED Platform and capable of performing all IFA process steps automatically.

Slide Barcode Reader

provides slide traceability. AESKUSLIDES and barcoded e.g. type, lot, etc. and a unique serial number, ensuring front end traceability and compliance with lab accreditation.

Sample barcode reader

ensures sample traceability and eliminates time and error.

New Multi-Rack

gives high flexibility, accepts most tubes.

Built-in LED microscope, incorporating NIKON based optics

is complemented by the AESKU engineered motorized mount ensuring both accuracy and speed.

The camera performs high tech autofocus algorithms storing multiple images per well.

HELIOS provides a revolutionary immunofluorescence platform incorporating many benefits in a single machine, including:

-

full traceability

-

no darkroom needed

-

slide processing and reading

-

powerful integrated image pre-classification tool

-

standardization of IFA

-

homogeneous working protocol

-

resource optimization

-

increased throughput

-

saves both time and money

-

simple implementation lab routine

Efficient

Traceability

Increase productivity with a fully integrated, high throughput system.

Ensure laboratory accreditation compliance with a sample and slide barcode reader that traces the whole process.

-

Built-in LED microscope captures images

-

Software suggests sample pre-classification positive/negative and pattern for processed slides which can then be sorted to save time

-

Patented sample probe with 3 independent needles improves slide processing speed, prevents slides from drying out and reduces the risk of contamination

-

Barcode readers ensure sample and slide traceability and eliminate time and errors associated with manually entering long patient ID numbers

-

AESKUSLIDES IFA slides are barcoded with all necessary information (reference, lot, etc.) including a unique serial number

Automation

Reduce hands-on time and improve standardization through a completely automated IFA process.

-

HELIOS processor performs all IFA process steps automatically

-

Built-in camera performs high tech autofocus algorithms so that clear pictures from the wells are stored according to user specified positions

-

Mounting medium dispenses to complete processing

Small Footprint

Maximize lab space with a compact all-in-one system.

-

Slide processing and reading in one system

-

No darkroom needed

Featured video

Photo Gallery

Specification

Slide capacity: Up to 20 slides

Sample capacity: Up to 190 barcoded samples

Sample tubes:

-

Height: 50-100 mm (1.97-3.94 in)

-

Diameter: 12-16 mm (0.47-0.63 in)

Sample microtubes: Yes

Sample barcode reader: Yes

Minimum sample volume: 50 µL

Minimum pipetting volume: 1 µL

Image capture: Validated 3 images/well (1-10 images)

Integrated LED microscope (Nikon-based optics): Yes

Positive and negative discrimination: Yes (ANA, ANCA, dsDNA)

Pattern preclassification: Up to 7 patterns (for Hep-2)

Integrated pattern database: Yes

Slide barcode reader: Yes

Full slide traceability: Yes

Titer estimation: Yes

Sample dilutions: 1:20480

Manual step between processing and reading: No

Manual mounting media dispensing needed: No

Number of substrates in the same run: Up to 4

Dimensions: (W x D x H)65 x 75 x 57 cm (25.6 x 29.6 x 22.5 in)

Weight: 33 kg (73 lb)

Voltage: 100-240 V

Frequency: 50/60 Hz

Power: 75 W

Operational temperature: 20-35°C